Capabilities

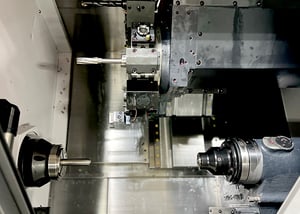

CapabilitiesEEC has over 20 pieces of precision machining equipment including CNC Lathes, Wire EDMs, and CMM inspection stations. This equipment is capable of producing custom parts and hardware for complex and highly engineered designs.

To help our customers get new assemblies to market quickly, meet their objectives, and stay ahead of competition, EEC offers quick-turn proof-of-concept prototypes. Our goal is to assist Engineers and designers by simplifying their design and proof-of-concept activities.

Our capable Engineering team can support your project from permanent magnet design concept, to prototyping, to hardware design and machining, and finally into production. The services offered by our qualified team help bridge the gap between hardware machining and magnet manufacturing, tying the entire process together.

Parts

PartsEEC produces customized hardware including various types of rotors, endcaps, and carbon fiber parts for our customers.

Other machined metal parts in our portfolio include rotor sleeves and rotor shafts with features like splines, gearing, keyways.

Our precision machining work and experience include common materials such as:

EEC is ISO 9001:2015 and AS9100D certified. EEC continues to invest in our business in order to provide customers with best-in-class service. ISO 9001:2015 and AS9100D is the basis for EEC’s internal quality management system, as many of its customers are in highly regulated industries, which require their own compliance to the standards.

EEC’s magnet products are used in equipment and assemblies across a variety of industries. From high-speed surgical drills to satellites in Earth’s orbit, EEC has a solution for you.

Through a variety of services and capabilities, EEC works as an extension of the customer to provide first-rate magnet products. EEC can help with:

PRIVACY