Electron Energy Corporation is your source for custom magnets and magnet assemblies for use in semiconductor and wafer applications. With over 50 years of experience, the team at EEC is fully capable of taking on challenging designs that maximize magnet circuit performance and miniaturize components.

At EEC's Material Technology Center, custom grades of samarium cobalt magnets can be alloyed, pressed, and sintered on-site. This allows EEC to rapidly develop unique grades of magnet material that provide increased energy product, increased temperature stabilization, and increased operating temperatures.

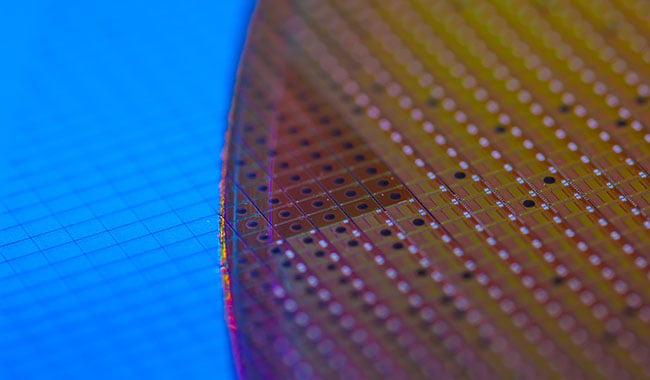

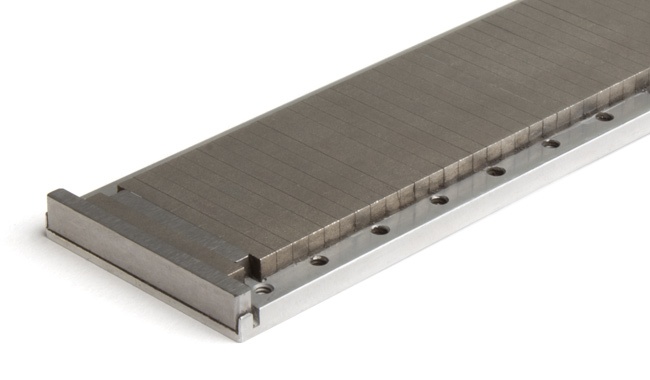

EEC can provide high precision magnet assemblies for all types of semiconductor and wafer applications. Our team is experienced at creating high tolerance magnet assemblies and miniature magnet components.

EEC has extensive experience designing and producing precision magnet assemblies used on thin film deposition equipment used in the semiconductor industry.

Customized magnet components can be made to support semiconductor manufacturing equipment.

MORE INFORMATION

Permanent magnets assemblies are used in sensor devices to measure properties such as direction, rotation, angle and current by detecting magnetic fields.

EEC offers various grades of permanent magnet materials to fit the individual requirements for any sensor application.

MORE INFORMATION

As a producer of permanent magnet materials, EEC has a deep understanding of the science behind the materials. This allows for superior product development and time to market due to the reduction of costly defects. This additional insight separates EEC from competitors and allows its engineering team to provide best-in-class service to customers. EEC’s application engineering team works closely with customers to develop magnet solutions and optimize design performance. In addition to application engineering, EEC also provides contracted engineering support and research and development services.

EEC’s magnet products are used in equipment and assemblies across a variety of industries. From high-speed surgical drills to satellites in Earth’s orbit, EEC has a solution for you.

Through a variety of services and capabilities, EEC works as an extension of the customer to provide first-rate magnet products. EEC can help with:

PRIVACY