MATERIAL DEVELOPMENT

EEC has a broad and deep portfolio of permanent magnet material grades (neodymium iron boron, samarium cobalt, and alnico) to satisfy virtually any application requirement. These standard material grades provide customers with a large selection of existing products that can be customized quickly and cost effectively if required.

As the first permanent magnet manufacturer in the world to commercially produce samarium cobalt (SmCo), EEC continues to deliver innovations with SmCo through the development of new high-performance grades. In order to deliver certain high performance and high quality SmCo grades customers require, EEC has continued to maintain a vertically integrated production process in North America in order to control the quality at every step of the production process.

Below is a summary of that process flow today.

Induction Melting: EEC purchases pure raw materials-Sm, Co, Fe, Cu, & Zr for the in-house production of SmCo 1:5 & 2:17 alloys. Pure metals are alloyed in an inert gas using an induction melting furnace. Precise control of alloy chemistry allows EEC to produce a wide range of materials to meet your demanding requirements.

Crushing: Rare earth alloys (inter-metallic compounds) are crushed to powders with an average particle size of ≈ 250 microns.

Milling; We process crushed alloy powder by ball or jet milling and reduce the average particle size to ≈ 3 microns. Because the resulting fine powder is chemically reactive and pyrophoric in nature, it requires protection from air (oxygen) using inert gas.

Blending: Our ability to precisely control material compositions during the blending operation helps us achieve specific magnetic properties.

Pressing: Released production powders with predetermined magnetic properties are pressed into green compacts using either axial, transverse, or isostatic presses. The pressing force and magnetic alignment direction is parallel for axial presses, but perpendicular for transverse presses. Isostatic pressing provides equal pressure from all directions for pre-aligned powder.

Sintering: Densification and the development of magnetic properties are accomplished through sinter, solution and aging processes in the presence of a vacuum or an inert gas.

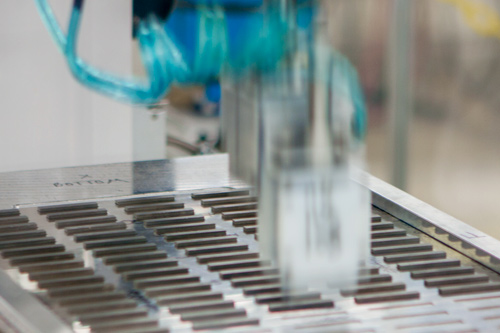

Machining: Sintered rare earth magnets, because of their brittle nature, are machined to final dimensions using grinding, slicing, or wire EDM technology.

Magnetization, Testing, & Quality Assurance: Magnetization, stabilization and testing of rare earth magnets are done to satisfy your specific requirements.

MACHINING OF CUSTOM MAGNET SOLUTIONS

Our 85,000 square feet of manufacturing space houses a variety of machining capabilities that allow EEC to deliver high tolerance parts for demanding applications.

- WEDM

- Ram EDM

- CNC Machining

- Grinders (various types)

- Slicers

ASSEMBLIES

EEC is able to provide high quality magnet assemblies for any application. Our experience in assemblies has allowed us to develop an expertise in common considerations such as adhesives, bonding, performance optimization, and design for manufacturability.

- Adhesion

- Sleeving

- Custom Packaging

- Clean Room Capabilities (Class 10,000)

MAGNETIZATION & TESTING

Because EEC must be an expert permanent magnet manufacturer in order to develop its own unique materials, we have a deep understanding of material properties. This knowledge is utilized in our extensive ability to magnetize and test magnetic properties of magnet solutions.

- Magnetizing and Magnet Adjusting Equipment

- Automated plotter

- Magnetic characterization

- Automated magnetic Testing Equipment

FINISHING

EEC is able to provide consultation and services for any finishing operation required for a magnet solution.

- Calibration

- Balancing

- Plating

- Coating

.jpg?width=926&height=176&name=eec_cmyk_notag-(maroon).jpg)

.png?width=949&name=eec_cmyk_notag-(white).png)