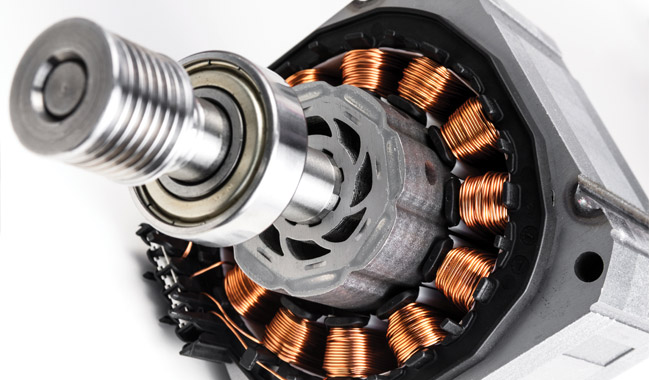

Magnet rotor assemblies are critical to high performance equipment and systems in a variety of industries and applications. EEC provides high quality materials and engineering expertise to create rotor assemblies for design-critical businesses within aerospace, oil and gas, and motor-dependent industries. Our unique ability to manufacture and design our own magnetic materials and assemblies in-house allows EEC to customize solutions and modify magnetic fields to enhance the final product.

QUICK-TURN PROTOTYPES

To help our customers get new products to market quickly, meet their objectives, and stay ahead of competition, EEC offers quick-turn proof-of-concept prototypes.

Our goal is to assist engineers and designers by shortening and simplifying their design and proof-of-concept activities. Our quick-turn prototyping program is dedicated to providing our customers with finished prototypes in as little as two weeks* to expedite proof of concept and new product evaluation.

Deliveries of prototypes are dependent on:

- Material and grade selection

- Part size and geometry

*Typical deliveries include a certificate of conformance only (additional requirements may require additional time).

Contact us to find out more about our prototyping capabilities.

MATERIAL SELECTION

Selecting the correct permanent magnet material and grade is critical in any magnet design. There are a few key parameters that should be carefully considered when evaluating the right material selection for your application:

- Maximum Operating Temperature: Determine the maximum operating temperature for your applications. Permanent magnet materials have specific operating temperature limits.

- Maximum Energy Product: Select the permanent magnet material that best “fits” your application requirements. Increased energy product will typically reduce the maximum operating temperature.

- Intrinsic Coercivity (resistance to demagnetization): Select a material that will perform in your application’s environment. the intrinsic coercitivty must be high enough to withstand the demagnetization forces inherent in the application.

FEA MODELING

At Electron Energy Corporation, our engineering team works closely with customers to provide a virtual in-house magnet technology resource when it comes to prototype design and fabrication. We use 2D and 3D Finite Element Analysis to solve the most demanding engineering challenges. Also, our in-depth knowledge of magnetic materials and decades of practical magnet and magnet assembly experience enable us to provide innovative solutions for our customers and ensure that their precise magnetic requirements are met. FEA offers many advantages over traditional trial-and-error prototyping, helping you bring your product to market faster:

- FEA is more cost effective than making prototypes

- FEA can provide faster solutions than prototyping

- Using FEA, the design can be optimized to enhance the performance of your system or device

- More alternative designs can be examined to improve quality, increase product life and customer satisfaction

.jpg?width=926&height=176&name=eec_cmyk_notag-(maroon).jpg)

.png?width=949&name=eec_cmyk_notag-(white).png)